Higlue PC 7218/PC9313 Wearing Compound Epoxy Adhesive

Basic Info

| Model NO. | Wearing Compound |

| Material | Epoxy |

| Classification | Room Curing |

| Main Agent Composition | Inorganic Adhesive Material |

| Characteristic | Wear Resistance |

| Promoter Composition | Curing Agent |

| Composition | Inorganic Material |

| Color | Grey/Yellow |

| Transport Package | 500g/Set, 5kg/Set, 10kg/Set, 13.7kg/Set and 20kg/S |

| Specification | 8kg/10kg |

| Trademark | Higlue |

| Origin | Jiangxi |

| HS Code | 3506100090 |

| Production Capacity | 50000PCS/Day |

Product Description

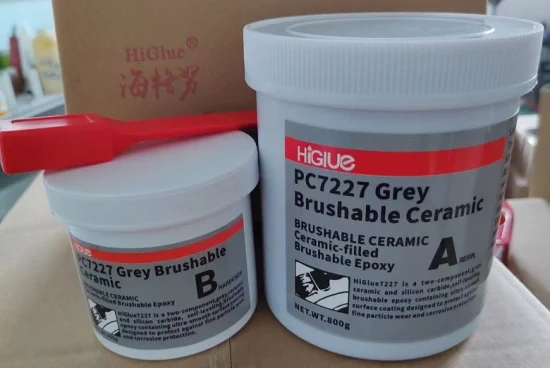

Epoxy Coating Ceramic Wearing CompoundChina Direct Factory PC 7218 Grey Wearing Compound

Ceramic beads filled epoxy repair putty is made up of high performance wear resistant and wear resistant ceramic particles and modified toughening and heat-resistant resin.

- Protects metals from course particle abrasion

- Applied by trowel

- Suitable for chemical attack applications

- Renews worn surfaces fast

| Application method | Trowel |

| Applications | Protective Coating |

| Color | Gray |

| Cure type | Room Temperature (Ambient) Cure, Two Component Mix |

| Drying time | 7.0 hr. |

| Key characteristics | Abrasion Resistant, Prolongs Equipment Life, Renews Worn Surfaces, Sag: Non-Sag, Wear Resistant |

| Mix ratio, by volume | 2 : 1 |

| Particle size | Large |

| Physical form | Paste |

| Substrates | Metal |

1. Cyclone and separator bodies

2. Dust collectors and exhausters

3. Pump liners and impellers

4. Fan blades and housings

5. Chutes and hoppers

6. Elbows and transition points

1. Cleaning:Remove dirt,oil, grease,loose flanky rust etc.,with a suitable high pressure water cleaning system .

2. Blasting:Blast all surfaces to be coated,with a sharp edged angular grit,such as aluminum oxide,to a depth of profile of approximately 75 microns and a degree of cleaniness of very thorough Blast Claeaning/Near Whitef.3. Cleaning:After blasting metal surfaces should be cleaned with a waterless or solvent,and allow the surface to dry before application of the product coat the surface before any oxidation or contamination takes place.4.Protection From Flash Rusting:To avoid flash rust,repairs should be made as soon as possible or within a mixmum 2 hours of blasting.5. Mixing The Material:Measure 2 parts resin to 1 part hardener by volume or weight if doing a partial kit.Otherwise,mixing a full kit is pre-measured at the correct ratio.For a full kit mix ,a spiral mixing blade attached to a high torque electric or pneumatic drill can be used.For a partial kit transfer measured quantities onto a clean and dry mixing surface to mix together witha trowel until uniform in color.If resin and hardener temperatures are 15ºC or below,preheat resin only,to about 30ºC but not to exceed 40ºC.6. Application:Apply fully mixed material to the prepared surface.Initially apply the material in a very thin layer to "wet" out the surface and ensure full epoxy contact with the roughened surface. Build up to desired thickness(minimum 6 mm),avoiding air entrapment.At 25ºC,the working time is 15 minutes and functional cure time is 4 hours Working and cure time depend on temperature and mass the higher the temperature and the larger the mass,the faster the cure.

Packaging & Shipping500g/set, 5kg/set, 10kg/set, 13.7kg/set and 20kg/set10kg/set carton size: 32x32x32.5

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory which over 20 years of experience,and provide you direct prices

Q: Can I be your agent?

A: Sure, we are looking for agent all over the world

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: If I am not satisfied with the products ,when I get it,what should I do?

A: If not satisfied it, please feel free to contact salesman soon, we will provide you the solution ASAP.