Loctiter PC 9313 Wearing Compound, Ceramic Bead Filled Epoxy Adhesive

Loctiter PC 9313 Wearing Compound, Ceramic Bead Filled Epoxy Adhesive Higlue Wearing Compounds combine the superior wear;

Basic Info

| Model NO. | Wearing Compound |

| CAS No. | 7085-85-0 |

| Formula | Mixture |

| EINECS | 230-391-5 |

| Bonding Function | Structural Adhesive |

| Morphology | Paste |

| Application | Automobile, Construction, Woodworking, Footwear & Leather, Fiber & Garment, Packing |

| Material | Epoxy |

| Classification | Room Curing |

| Main Agent Composition | Epoxy |

| Characteristic | Impact Resistance, Arosion Resistance |

| Promoter Composition | Curing Agent |

| Composition | Inorganic Material |

| Color | Grey |

| Product Name | High Impact PC 9313 Wear and Abrasion Resistant We |

| Keywords | Wearing Compound |

| OEM | Available |

| Using | Mainly Used for Mining |

| Package Available | 1kg or 10kgs or More |

| Sample to Test | Yes |

| Shelf Time | 1~2 Years |

| Other Name | Alumina Ceramic Bead Filled Wear Compound |

| Transport Package | Carton |

| Specification | 10kg |

| Trademark | Higlue |

| Origin | Jiangxi China |

| HS Code | 3506100090 |

| Production Capacity | 20000PCS/Month |

Product Description

Loctiter PC 9313 Wearing Compound, Ceramic Bead Filled Epoxy AdhesiveHiglue Wearing Compounds combine the superior wear properties of ceramic and the convenience of two-part epoxies to protect equipment from corrosion, abrasion, and other wear encountered in harsh industrial environments. Available in trowelable and brushable formulations with special fillers for tough conditions.Ceramic beads filled epoxy repair putty is made up of high performance wear resistant and wear resistant ceramic particles and modified toughening and heat-resistant resin.Ceramic beads wear resistant epoxy coating is widely used in repairing all kinds of wear parts and preparing wear-resistant and corrosion-resistant coatings on the surface of all kinds of machine parts. For example: repair and pre-protection of pipeline, elbow, mud pump, sand pump, centrifuge, packing box, slurry circulating pump body, impeller, size head of power plant desulfurization system, etc.

Features:

1. Ceramic-filled for outstanding resistance to abrasion;

2. Renews worn surfaces fast-reduces downtime;

3. Extends wear life- resists sliding abrasive wear and eliminates costly wear part inventory;

4. Non sag- provides abrasion resistance on over-head and vertical surfaces.Ceramic Repair Putty* Renews worn surfaces fast and reduces* Downtime to put equipment back in service* Quickly Easy to mix and use* Non-sag paste allows application* Versatility for overhead& vertical surfaces* Non-shrinking* Extends wear life* Resists sliding abrasive wear* Eliminates costly wear part* Inventory Can be re-applied to* itself Contains ceramic beads 1-1.5mm.Technical Information

| Product Type | Ceramic Repair Putty/ Abrasion Resistant Coating/ Wear Resistant Epoxy |

| Resistant Properties | Corrosion-Resistant |

| Pear Dia. | 1- 1.5mm (can be customized) |

| Color | Grey (can be customized) |

| Mix Ratio by weight | 8:1 |

| Mix Ratio by volume | 4:1 |

| Working temperature | 149ºC |

| Package Weight | 30 lb per kit |

| working time | 45-65 mins |

| Compressive strength(GB/T1041): | 112.0MPa |

| Tensile strength(GB/T6329): | 32.0MPa |

| Shear strength(GB/T7124): | 14.0MPa |

| Flexural strength(GB/T9341): | 45.0MPa |

| Fully curing time | 16-24 hours |

| Shelf Life | 12 month |

Application

1. Cyclone and separator bodies

2. Dust collectors and exhausters

3. Pump liners and impellers

4. Fan blades and housings

5. Chutes and hoppers

6. Elbows and transition points

How to use

1. Surface treatment: roughening the parts to be treated, sanding or sandblasting with an angle grinder, etc.; cleaning the roughened surface; the treated surface should be a rough and dry fresh substrate surface, and should be No oil and dust.2. Preparation: Mix the components A and B of the small particle wear-resistant protective agent according to the mass ratio A:B=2:1, and use them within 30 minutes.3. Coating: apply the uniformly mixed small particles of wear-resistant protective agent layer by layer to the area to be repaired, preferably at a thickness of 3-10 mm. The adhesive layer should be compacted to fully infiltrate the substrate; after the coating is applied to the required size, the surface layer is smoothed.4. Curing: Curing at 25ºC for 16 hours can be put into use. When the temperature is lower than 10 degrees, it can be cured by baking with an iodine tungsten lamp or electric heating plate for 2 hours.

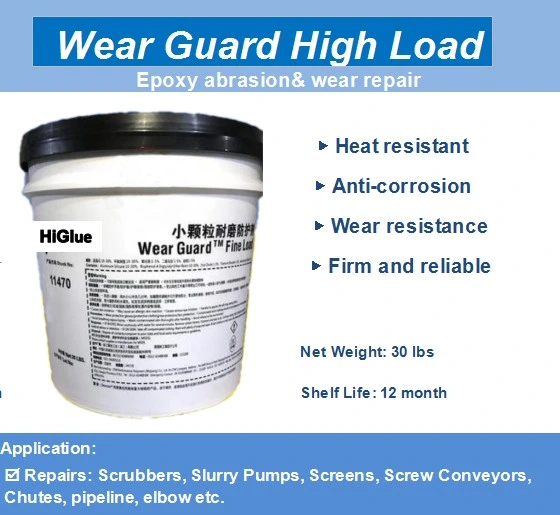

Packing & Shipping 500g/set, 5kg/set, 10kg/set, 13.7kg/set and 20kg/set10kg/set carton size: 32x32x32.5Our CompanyJiangxi Gooz Adhesive We are an innovative enterprise based on research and development, production and marketing. Over 20 years experience helps us take a leading position in adhesive filed. We supply good and stable quality glue for clients all over the world. Now we have a various business network over Middle East, Europe, America, Southeast Asia and our own mainland. And won great reputation among them. We cherish our long term cooperation relationship with old clients, and also looking forward to develop more businesses with new clients.Products:1. HiGlue liquid thread locker: 222 242 243 262 270 271 272 277 2902. HiGlue pipe thread sealant: 545 554 565 567 569 577 542 561 L553. HiGlue instant super glue: 401 403 406 407 410 411 412 414 415 454 460 480 495 4964. HiGlue flange/ plane sealant: 510 515 518 5182 5208 573 5745. HiGlue silicone rubber: 207 587 593 594 595 596 598 5020 5699 5900 5910 59206. HiGlue retaining compound: 603 6050 609 620 638 641 648 6482 660 661 662 680 60017. HiGlue surface treatment: 7075 7452 7649 7387 7471 770 754 7908. HiGlue Metal Epoxy Putty: 111 112 113 1149. HiGlue Epoxy Tile Grout And Epoxy Anchor10. HiGlue wear guard high load 11490/11470

Certification

Q: Are you trading company or manufacturer ?

A: We are factory which over 20 years of experience,and provide you direct prices

Q: Can I be your agent?

A: Sure, we are looking for agent all over the world

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: If I am not satisfied with the products ,when I get it,what should I do?

A: If not satisfied it, please feel free to contact salesman soon, we will provide you the solution ASAP.

You may also like

Send inquiry

Send now